|

|

Before posting a question in the forum, please take a look if your question can be answered by any of the frequently asked questions: Frequently asked questions: Q: Can the TP10/RC be used with both E-bus and K-bus? A:

- Due to the way K-bus works, the DIOC protocol will not function properly if any input/output on the K-bus is allotted to a faster cycle time then the dioc input/output.

- If the amount of inputs/outputs of the K-bus is too large, the I/O cycle time will get offset by too much, causing the DIOC protocol to not function properly.

- As such, K-bus is not officially supported for the TP10/RA/RC.

Q: What are the specifications of the sensors in the TP10/RA? A:

- The room temperature measurement has the following specification:

Accuracy (typ 0 - 65 degrees C): +/- 0.3 degrees C

Repeatability: 0.06 degrees C

Resolution (sensor): 0.015 degrees C

Range (sensor): -40 to 125 degrees C (DIOC range limited to -20 to +120 degrees)

Long term drift: < 0.03 degreesC / year

- The room humidity measurement has the following specification:

Accuracy: +/- 3% RH

Repeatability: 0.10% RH

Resolution (sensor): 0.01% RH

Hysteresis (at 25 degrees C): +/- 0.8% RH

Range: 0 to 100% RH

Long term drift: < 0.25% RH/ year

- The room eCO2 measurement has the following specification:

Baseline stabilisation time < 10s

Range: 400 - 1600 ppm

Resolution (sensor): 1 ppm

Resolution (system): 1 ppm

Range (system): 0-1600 ppm

estimated lifetime : 50 years, because of low stress usage in the TP10/RA

- The room VOC measurement has the following specification:

Baseline stabilisation time < 48h

Range: 0 - 1187 ppb

Resolution (sensor): 1 ppb

Resolution (system): 1 ppm

Range (system): 0-1187 ppm

Troubleshooting: Q:TP10/RA starts normally, but does not react to button usage. A:

- The protective sticker is still on the glass plate of the TP10, this is a plastic that can cause the TP10 buttons to not react.

- The masks of the leds are enabled.

Q:TP10/RA leds blink randomly or buttons get pushed without anybody being near the TP10/RA. A:

- The GND of the TP10/RA is not propperly grounded. If it is connected to the 0V line of the PLC, then this line should be grounded. A difference in electrical potential between the tp10 and it's surroundings can cause the buttons to activate. Grounding the GND of the TP10/RA will stop this from happening.

Q:TP10/RA keeps blinking, but does not start working. A:

- The input of the PLC is not connected to the output of the TP10/RA.

- The springs on the back of the TP10/RA do not connect to the backplate.

- The TP10/RA is not mounted properly.

- The input/output of the PLC used for the TP10/RA do not match eachother.

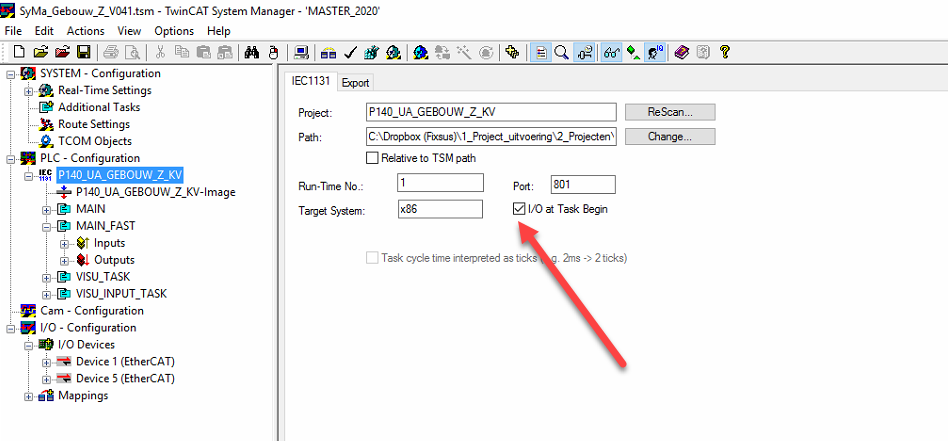

- I/O at task Begin is not activated in the system manager.

Q:TP10/RA reacts to button touches, but messages do not make it to the PLC. A:

- the voltage that the PLC provides dips below 22V. Upping the voltage supplied to 26V might solve the problem.

Q:Whilst starting up The PLC/Ethercat connection malfunctions. A:

- More then 4 dioc devices are being started at the same time. The capacitors of the devices pull a current that is too high which causes the supply to fail. Starting the DIOC devices one by one should fix this problem. IF the problem persists, check if the power supply is big enough for all devices.

Q:Not all messages received by the TP10/RC are correct. A:

- 'I/O at task begin' is not enabled in the system manager. This can be found under: PLC - configuration/*Project name* The 'I/O at task begin' box can be checked here.

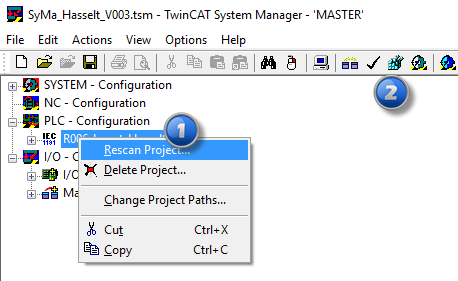

- linked program is not up to date. Right click the project name under PLC - configuration and click 'rescan project'. After re-enabling the configuration, the problem should be fixed.

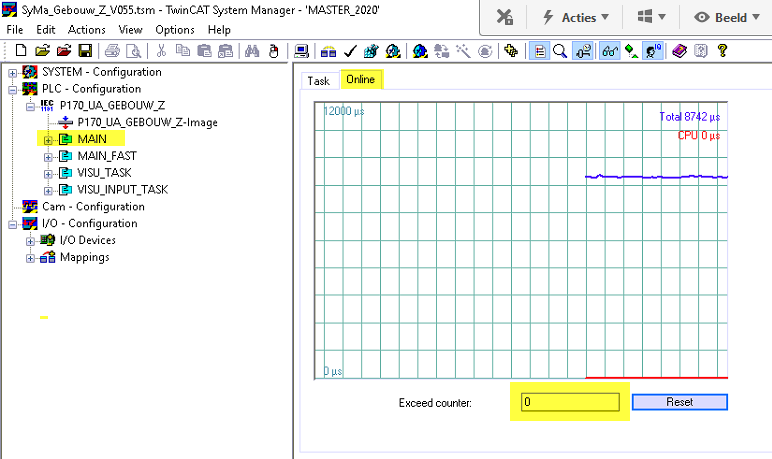

- The cycle time of the PLC goes over the limit.

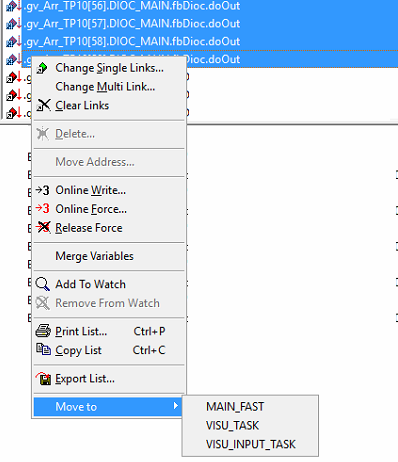

- The in or output of the TP10/VAV is being called in the wrong task.

- The program is not called every cycle, calling P_DIOC_MAIN every 2 cycles of 6ms does not ensure a perfect communication of 12ms.

Q:TP10/RA starts normally, but does not Always react to button usage. A:

- see 'Not all messages received by the TP10/RC are correct.'

If these Answers do not help you along, please make a post in the Programming forumEdited by moderator Thursday, March 15, 2018 12:09:19 PM(UTC)

| Reason: added some extra solutions

|

|

|

|

|

|

Forum Jump

You cannot post new topics in this forum.

You cannot reply to topics in this forum.

You cannot delete your posts in this forum.

You cannot edit your posts in this forum.

You cannot create polls in this forum.

You cannot vote in polls in this forum.